History

Company founded in Minden

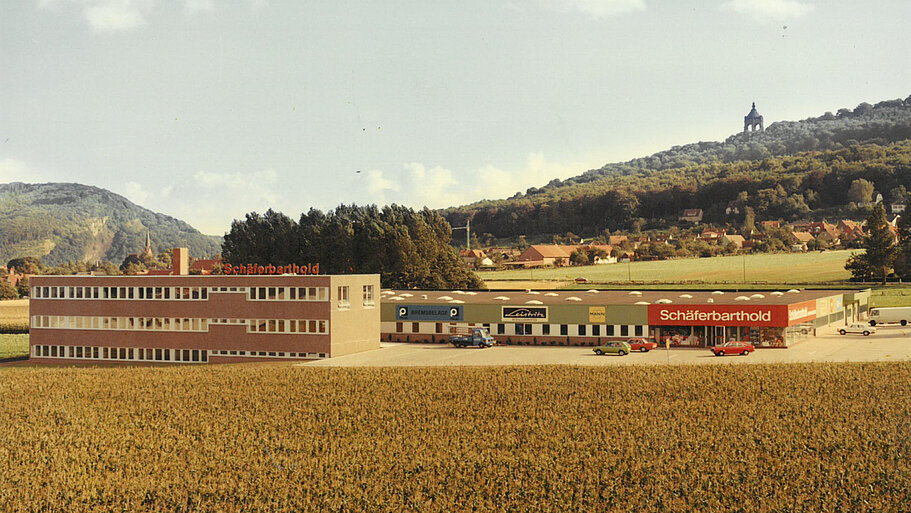

Relocation to Porta Westfalica

Warehouse extension

Initial certification

New administration building

Aerial view of the company premises

Expansion of logistics facility

Expansion of specialist trade, launch of new corporate identity

Expansion of logistics facility